I recently transplanted a Blue Spruce tree on my property. I use a red garden hose from my house to water the tree. I use an automatic water timer to water the tree. The automatic water timer waters at noon and midnight every day. I am away at work at noon and sleep at midnight. I need to verify that the tree is receiving water. The purpose of this post is to verify that the transplanted tree is receiving water.

Thermal Analysis

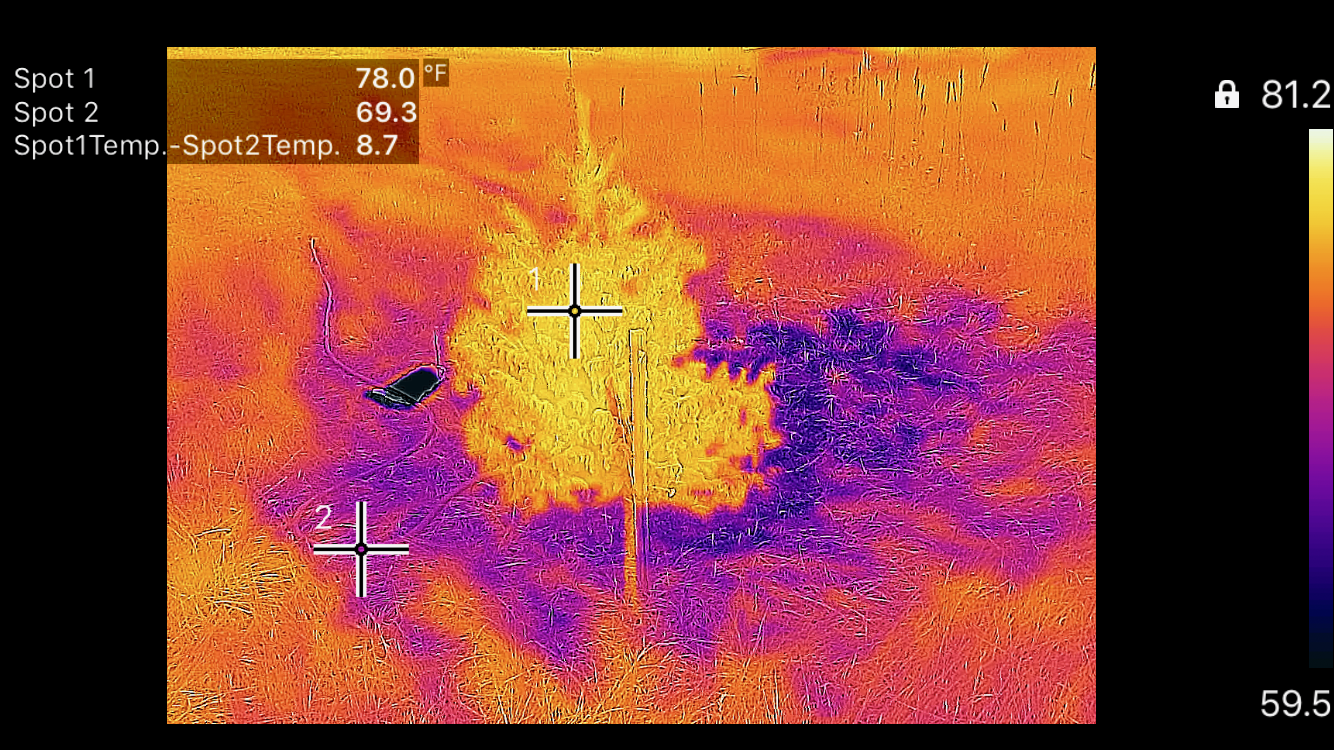

The physical process of evaporation causes surfaces to cool. At 8:15pm on 6/7/18, I utilized my FLIR One Pro infrared camera to capture a visible light and infrared image of my transplanted tree. The emissivity of trees is generally around .98 so the camera was set to this value. It is reasonable to believe that the emissivity of grass will be similar to the tree because they are both organic plants. An emissivity setting of .98 is reasonable in the infrared image shown because the garden hose is made of rubber with

a high emissivity and there are no sharp changes in apparent temperature in the image as the garden hose interacts with the grass vegetation. The reflected background temperature was determined to be 32.2 degrees Fahrenheit. The tin foil used to determine the reflected background temperature is visible in the infrared and visible light image. The tin foil has a very low inherent temperature due to its low emissivity and reflective nature.

Infrared Analysis Results

The results of the infrared imaging analysis suggest that the tree is receiving water. Evaporative patterns can be observed along the base of the tree. In fact, it appears that too much water is being supplied to the tree because evaporative patterns can be observed in the image running downhill. Corrective action is to reduce the amount of water being supplied to the tree.